Overview

MANTRA has already commissioned coating and lamination pilot plan machineries from M/s Matex, Italy (Multilab 900) and M/s Santex, Switzerland (Cavimelt TSM). MANTRA has already developed several samples on this machine. MANTRA has developed PVC, polyurethane, acrylates coated and laminated products, viz, artificial leather shoes cover, filter fabrics protective fabrics, garments, umbrella fabric, etc.

MANTRA has developed modern testing laboratory to test various technical textiles including coated and laminated products.

MANTRA has purchased several books on technical textiles and kept in the Library. MANTRA has allotted a separate space in its web site for technical textiles. MANTRA has also developed a product display centre and samples prepared by MANTRA as well those collected from various sources are displayed in this center and interested entrepreneurs who visit this centre are provided guidance about technical textiles.

MANTRA has started giving pilot plant trials on coating and laminating machines. Many entrepreneurs have taken advantage of sampling facility available in coating & lamination.

Centre of Excellence, MANTRA had submitted proposal to the Govt. of Gujarat for Nonwoven pilot facilities with a cost of Rs 10.00 crore. The proposal has been passed by the govt. of Gujarat and Rs. 6.53 crore has been sanctioned.

The proposal consists of 500 mm pilot scale machine with hydro entanglement, needle punch, thermo and chemical bonding, thus consisting facilities which can produce approx. 80-85% of all Nonwoven products. Further, instead of 4 different Web forming lines (for above four technologies), a single web forming system has been proposed. This is unique and nowhere available in the world. Further, because technical textiles, being an emerging and developing textile sector, MANTRA will be able to serve the prospective customer in product development and R&D in almost all areas of technical products.

As has mentioned before, the web formation line has been selected which is of Indian origin, generally used for staple spinning process. Indian machine manufacturing industries has the expertise and, in fact supply these machines to the market for long time now. In principle, the machine design / technology remain same, but our machines will be of lesser width. The hydro entanglement system will be of European origin and needle punch machine will be procured from korea. These machines has been already tested and running at other places successfully. As far as the quality and repeatability are concerned these are proven machinery/technology, we are certain that the quality of the products will also remain.

Equipments

| Sr. No. | Equipment / Tool | Company Make | Usage |

|---|---|---|---|

| 1. | Universal Strength Tester (5 Ton Capacity) | MTESTQuattro | Tensile strength test |

| 2. | Air Permeability Tester | TEXTTEST INSTRUMENTS | Air Permeability Test |

| 3. | Spray Rating Tester | WIRA INSTRUMENTATION | Spray Test |

| 4. | Weight Balance | M.G. Poonawala | Weight of specimen |

| 5. | Flex Tester DE-MATTIA | Asian Test Equipments | Cracking Test |

| 6. | Flex Tester SCHILD KNECHT | Asian Test Equipments | Cracking Test |

| 7. | Taber Abrasion Tester | TABER Industries | Taber Abrasion Test |

| 8. | Vertical Flammability Tester | - | Flammability Test |

| 9. | IV( intrinsic viscosity ) Test | Lauda Scintific | IV( intrinsic viscosity ) Test |

| 10. | Water resistance (Hydrostatic Head) | Textest | Hydrostatic Head |

| 11. | Thermal Conductivity Apparatus | SASMIRA | Thermal Conductivity Test |

| 12. | Liquid Wicking Rate Test Kit | WIRA INSTRUMENTATION | Wicking Test |

| 13. | Liquid Absorbency Time Test Kit | WIRA INSTRUMENTATION | Absorbency Test |

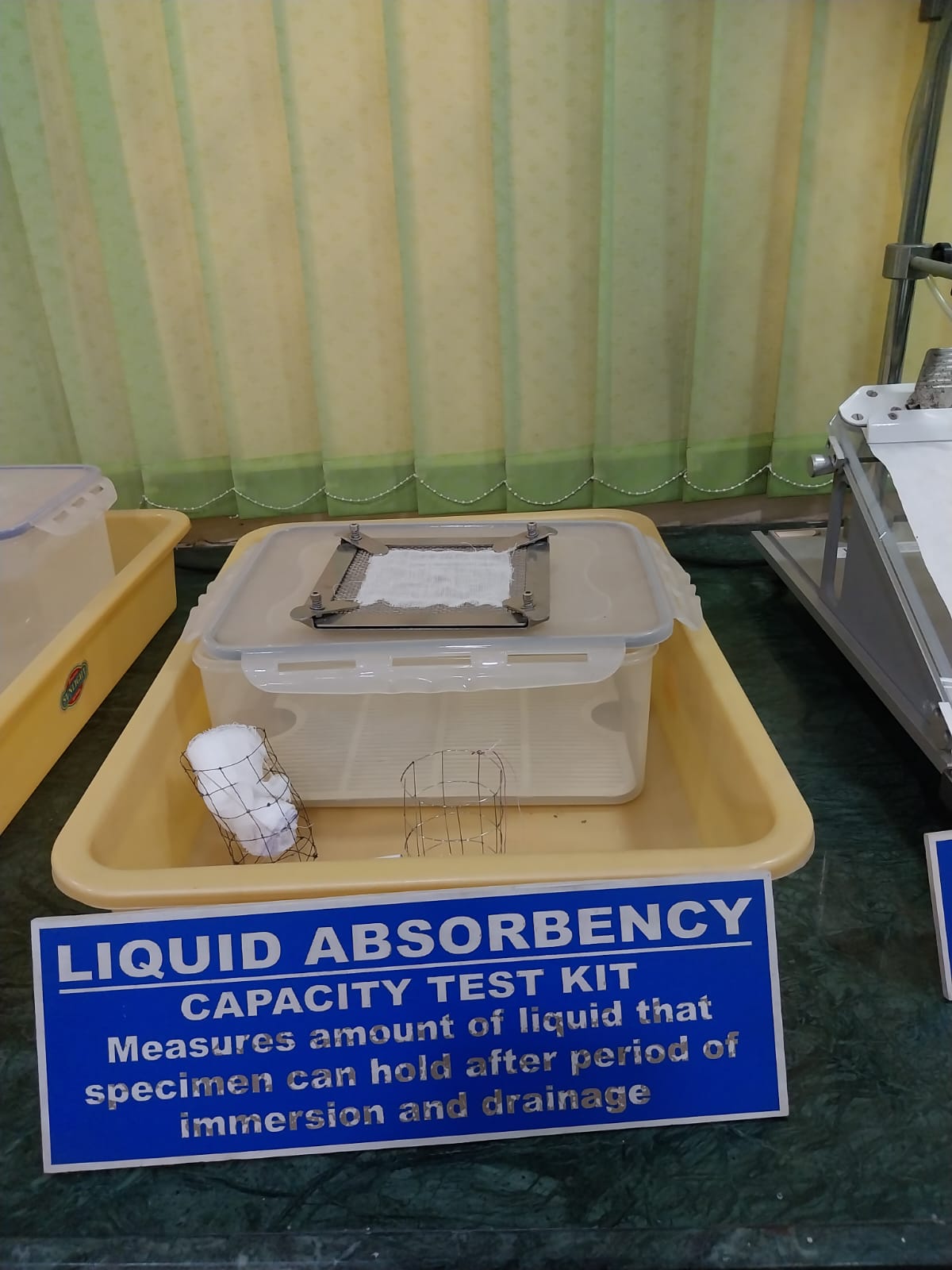

| 14. | Liquid Absorbency Capacity Test Kit | WIRA INSTRUMENTATION | Liquid Absorbency Capacity Test |

| 15. | TOG Tester | WIRA INSTRUMENTATION | TOG Test |

| 16. | WIRA Run-off Test Kit | WIRA INSTRUMENTATION | WIRA Run-off Test |

| 17. | Mask Differential Pressure Tester | Sataton | Mask Differential Pressure Test |

| 18. | 45° Degree Flammability Tester | Sataton | 45° Degree Flammability Test |

| 19. | Blood Penetration instrument | Sataton | Blood Penetration test |

| 20. | Mask Filter Efficiency | Sataton | Mask Filter Efficiency |

Testing Price List

| Parameters | Testing standards | Testing charges ₹ |

|---|---|---|

| Air Permeability of Textile Fabrics | ASTM D737-18 ISO 9237:1995 |

400 |

| Water Repellency: Spray Test | AATCC 22-2017 ISO 4920:2012 |

600 |

| Test Method for Vertical Wicking Rate of Textiles: to Specified Distances | AATCC TM 197-2022 | 500 |

| Test Methods for Nonwovens Part 6 Absorption (Liquid Wicking Rate) |

IS 15891 : Part 6 : ISO 9073-6: 2000 |

500 |

| Quilts Tog Test Specification for Quilts Containing Fillings other than Feather and/or Down (Tog Test) |

BS 5335-1:1991+A2:2010 | 2500 |

| Rubber or Plastics-coated Fabrics – Determination of Resistance to Damage by Flexing (DE-MATTIA) | IS 7016 : Part 4 : 2003 (Reaffirmed Year : 2019 ) ISO 7854: 1995 |

400 |

| Rubber or Plastics-coated Fabrics – Determination of Resistance to Damage by Flexing (SCHILD KNECHT) | IS 7016 : Part 4 : 2003 (Reaffirmed Year : 2019 ) ISO 7854: 1995 |

400 |

| Taber Abrasion Resistance of Textile Fabrics | ASTM D3884-22 ASTM D 4060-19 |

1200 |

| Flammability and Flame Resistance of Textile Fabrics. | IS 11871-1986 ASTM D 6413 ASTM D1230-22A |

500 |

| Inherent Viscosity (IV) of Polyester | ASTM D4603-18 | 1500 |

| Water Resistance Hydro head Water Cullman |

IS 7016 : Part 7 ISO 1420:2016 AATCC 127-2017 ISO 811:2018 ISO 9073-16 IS 391 IS 15891 P-16 BS 3424-26 |

800 |

| Medical face masks Differential Pressure Test | IS 16289 Annex C EN 14683:2019+AC |

500 |

| Synthetic Blood Penetration Resistance Test |

IS 16546 : 2016 ASTM F1670 |

5500 |

| Water Resistance: Impact Penetration Tester (WIRA Run-off Tester) | AATCC TM042 IS 17375 : 2020 ISO 9073-11 IS 15891-11 |

400 |

| Thermal Conductivity | SASMIRA tester | 500 |

| Tensile and Elongation test (Coated) | ISO 13934- IS 7016-2 |

700 |

| Tear strength | ISO 13937- ASTM D 4533 IS 7016-3 (Method A1) |

600 |

| Gram per Sq. Meter (GSM) | ISO 9073- IS 15891 -1 IS 14944 P-6.4 IS 7016 -1 |

200 |

| Water Holding Capacity | IS 14944 P-6.11.3 | 600 |

| Absorbency - Sinking Time | IS 14944 P-6.11.2 | 600 |

| Particulate filtration efficiency | ASTM F 2299/F2299M | 2000 |

| Splash Resistance (Blood) | ASTM F 1862 ISO 22609 IS 16289 Annex D |

5500 |

| Determination of the Resistance of Protective Clothing Materials to Penetration by Blood and Body Fluids - Test Method Using Synthetic Blood (Synthetic Blood Penetration Resistance Test) | IS 16546 : 2016 | 5500 |

| Surface Resistance | AATCC-76 ASTM D257 |

600 |

| Blocking Resistance | IS 7016-9:2023 | 500 |

| Coating Adhesive | IS 7016-5:2019 | 500 |

| Heat Ageing | IS 7016-8 | 7000 |

| Determination of water absorption time and water absorption capacity of textile fabrics | ISO-20158-2018 | 600 |

| Sanitary towels-specification Annex B : determination of water resistance of protective barrier (Cone test Method) Annex C: Method for Determination of absorbency capacity Annex D: Determination of moisture content Annex E: Determination of water soluble extract |

EAS 96:2008 Annex B Annex C, Annex D, Annex E |

600 |

Staff

| Sr. No. | Name | Designation | Expertise |

|---|---|---|---|

| 1. | Mahesh H. Baraiya | H.O.D., J.S.O. | R&D, Trial of Technical textile machine, Testing |

| 2. | Abhishek P. Dhameliya | Lab Assistant | Performance in machine & testing |

| 3. | Umesh J. Patel | Machine Operator | - |

| 4. | Rakesh S. Patel | Fitter/ Maintannace staff | - |

| 5. | Vallabh A. Patel | Fitter/ Maintannace staff | - |

Training

| Sr. No. | Staff Name | Name of Training | Date | Details | General / Inhouse / Training provided by MANTRA |

|---|---|---|---|---|---|

| 1. | Mahesh Baraiya | ISO 17025:2017 | 24-27 april 2024 | NABL | MANTRA |

| Kaizen | 16 & 30 Dec 2023 | Awareness | MANTRA | ||

| NABL Documentation | 30 Aug 2024 | NABL Documentation | MANTRA | ||

| Fire Safety | 19 june 2024 | Fire Safety Awareness | MANTRA | ||

| 2. | Abhishek Dhameliya | Kaizen | 16 & 30 Dec 2023 | Awareness | MANTRA |

| Fire Safety | 19 june 2024 | Fire Safety Awareness | MANTRA | ||

| 3. | Umeshbhai Patel | Fire Safety | 19 june 2024 | Fire Safety Awareness | MANTRA |

| Lamination and Coating machine training | - | Lamination and Coating machine training | MANTRA | ||

| Melt Spinning training | - | Melt Spinning training | MANTRA | ||

| Airjet Texturing machine Training | - | Airjet Texturing machine Training | MANTRA | ||

| Draw False twist Texturing machine training | - | Draw False twist Texturing machine training | MANTRA | ||

| 4. | Vallabhbhai Patel | Fire Safety | 19 june 2024 | Fire Safety Awareness | MANTRA |

| Carding, Spunlace, Needle punch machine Training | - | Carding, Spunlace, Needle punch machine Training | MANTRA | ||

| 5. | Rakeshbhai Patel | Fire Safety | 19 june 2024 | Fire Safety Awareness | MANTRA |

| Carding, Spunlace, Needle punch machine Training | - | Carding, Spunlace, Needle punch machine Training | MANTRA |

Air Permeability Tester

Air Permeability Tester Bursting Tester

Bursting Tester Coverstock Wetback

Coverstock Wetback Flexing Tester

Flexing Tester Rate Test Kit

Rate Test Kit Time Test Kit

Time Test Kit Liquid Absorbency

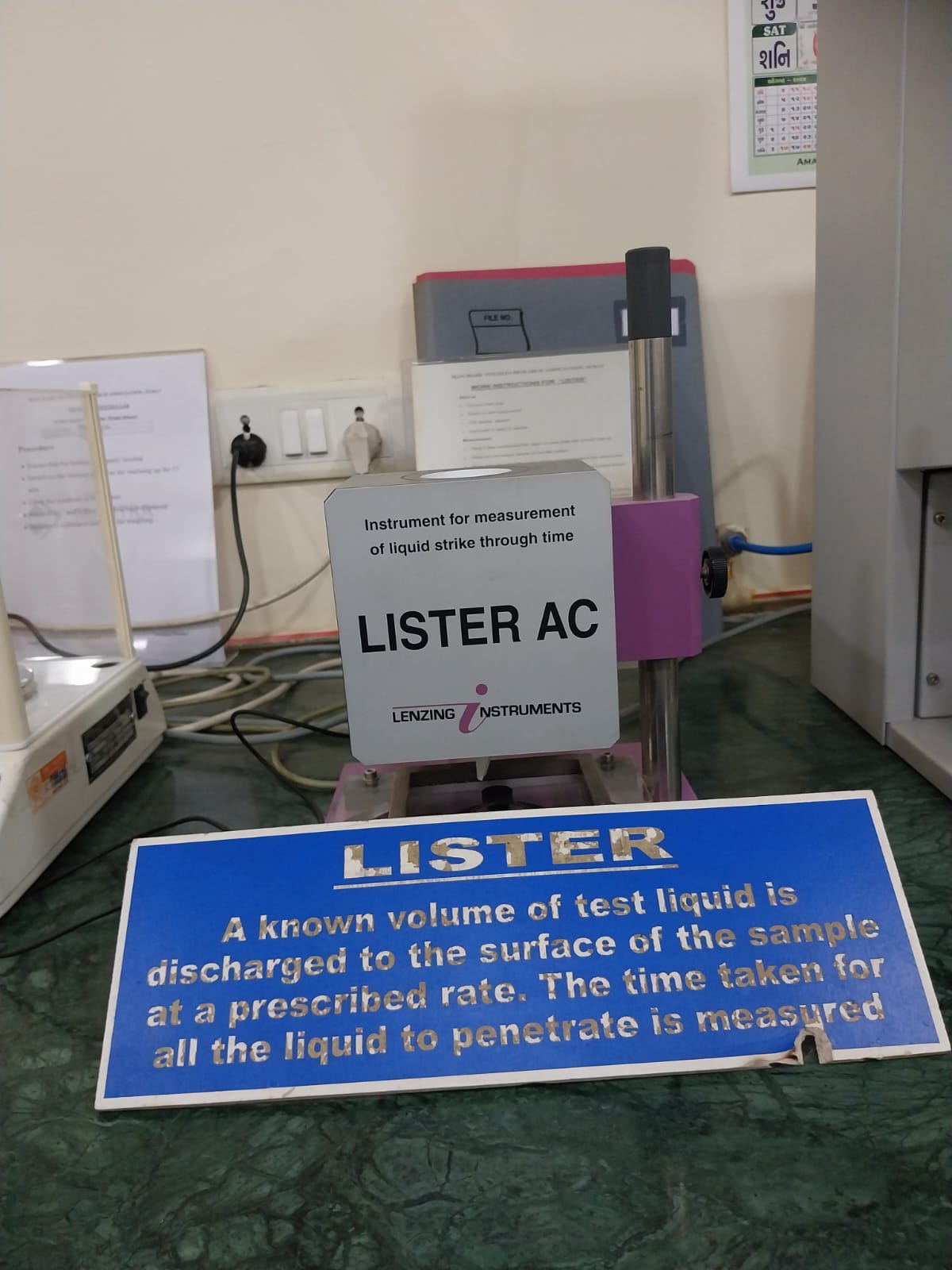

Liquid Absorbency Lister

Lister Magnifying Glass

Magnifying Glass Flexing Tester

Flexing Tester Shade Card Winding Machine

Shade Card Winding Machine Surface Resistance Tester

Surface Resistance Tester Taber Abrasion Tester

Taber Abrasion Tester Tensile Machine

Tensile Machine Thermal Conductivity Tester

Thermal Conductivity Tester Tog Tester

Tog Tester Vertical Flammability

Vertical Flammability Wira Run Off Test Kit

Wira Run Off Test Kit